Spout pouch is a kind of flexible packaging, it is used to pack liquid and solid products. These pouches are becoming more and more popular due to their economic benefits and environmental friendliness. You can customize the spout pouch by printing to make it more attractive to customers.

1. Steps of printing spout pouch

The following are steps for printing a spout pouch.

1) Step 1: Understand the material of the spout pouch

The product in the spout pouch needs to be protected, so you should be very sensitive when choosing materials. The spout pouch has different materials for the outer layer, the inner layer and the middle layer. For the inner layer, you will use low-density polyethene material and cast polypropylene. This is because this material can withstand high heat and heat sealing. The above features make your printed spout pouch contain and retain heat.

For the middle layer, you use aluminium foil. This is because they have good clarity and hardness. The melting point of aluminium foil and nylon is also very large. These features make your bag resistant to moisture and oxygen.

Printed Spout Pouch

The outer layer material of the bag is made of oriented polypropylene and polyethene terephthalate. Oriented polypropylene has great clarity, thus increasing the barrier properties of the spout pouch. The strength and temperature resistance of polyethene terephthalate. This helps prevent damage to both content and packaging.

In addition, it also provides temperature-resistant printing spout pouches. Discuss the various materials used to make spout pouches and explain how they determine the type of printing technology you will use. Wrap-around labels provide excellent marketing opportunities at a lower production cost and higher labelling speeds than self-adhesive labels.

2) Step 2: Select or design artwork/graphics to print in the Spout Pouch

Your choice of printed spray pocket artwork will depend on where you use it and also your budget. In addition, the content of your spray pocket will greatly determine your art selection. You must also consider the target market of your product, which enables you to invest in the design of your printed spout pouches. And by doing so, you can customize and design your nozzle bag to meet customer satisfaction requirements.

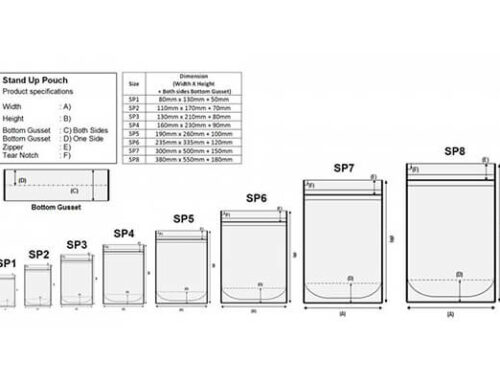

In addition, when designing your printed spout pouch, always make sure you customize it to make it unique from the competition. Be sure to design spout pouches of different shapes and sizes so that they can easily attract customers’ attention.

Spout Pouch Designs

When designing, we must remember that the content it can obtain is limited. Then you take the above into account. It allows you to take into account important factors such as the shape of the bag, its quality, and the number of printed spout pouches and its content. The choice of artwork will depend on the type of printing technique and you will use spout pouches.

3) Step 3: Choose spout pouch printing technology

There are various techniques you can use to print on your spray pocket. They include:

#1. Rotogravure Printing spout pouch

This is a long-term, high-quality, high-speed printing technology. Just like engraving, this technique can produce fine images on your spout pouch. The minimum limit for this printing technique is 10,000 bags. This technology can also provide you with 9 different colour printing options. When you use this technique, you will produce high-quality and low-cost spout pouches. Here, the image, design and text to be printed are engraved on the surface of the metal plate. Then fill the engraved area with special ink. Finally, rotate the plate on a cylinder, and then transfer the image and text to the spray pocket.

Rotogravure printing

Advantages of gravure printing Spout Pouch

- It can produce high-quality images.

- Low operating cost at high output.

- The printing cylinder runs through high capacity without reducing the image.

- This method can be used to print films with a wide range of thicknesses like nylon.

Limitations of gravure printing Spout Pouch

- Its start-up cost is very high, which means you have to make thousands of copies to make a profit.

- The preparation time of the cylinder is longer, so special skills are required.

- Gravure printing has rasterized text and lines.

#2. Digital printing Spout Pouches

This printing technique can be used when printing complex text and images on medium-quality surfaces. Here, inkjet-based printing technology is used, and brand and graphic elements are directly applied to the inkjet bag. There is no minimum running volume for this technique. The above statement simply means that you can print 200 to 20,000 bags, depending on your specifications. Digital printing technology produces expensive spout pouches.

Digital printer for spout pouch

Advantages of digital printing spout pouches

The advantages of digital printing for spout pouches are as follows:

- One of the outstanding advantages of this technique is that it does not involve boards.

- When using this technique, you will get very bright colours.

- This technology has the smallest set-up time, which allows you to get the best print value in a short time.

- Digital printing technology has the fastest turnaround time.

- Because this technology is widely adopted, many paper mills are producing a paper that can be used here.

- This gives you multiple options for the paper you want to use.

- This technique can add inline completion to the workflow.

Limitations of digital printing spout pouches

The limitations of spout pouch digital printing are as follows:

- As your print becomes longer, the quality of the print decreases in the spray pocket.

- You will not be able to use metallic ink to print on the spout pouch using this technique because the ink will short-circuit the printing machine. This is because the technology only uses CYMK ink.

- In addition, you can’t use this printing technology on spout pouches that hold food. This is because according to the Food and Drug Administration regulations that guide food packaging, the ink used is not allowed.

- It is very difficult to generate custom colours for your spout pouch because the printing technology uses the CYMK colour range better.

- If you use long-distance running, they are expensive.

- You can only use digital printing on certain papers, and the paper range used here is not strong.

- Compared with other printing technologies, spout pouches printed with digital printing technology tend to fade faster under direct sunlight.

#3. Flexo printing spout pouch

This technique is used for simple surface printing. This technique uses a flexible photopolymer plate, which you can wrap around a rotating cylinder to get every colour. Then the text of each colour is raised from the surface of the printing plate. Only the raised parts on the surface of the printing plate are inked and printed. It is a low-cost printing technology for printing simple text and images. This printing technique is very popular when printing large numbers of labels on spout pouches.

Flexo printing illustration

Advantages of flexographic printing spout pouches

The advantage is;

- Its versatility; it is versatile meaning you can use it in any non-absorbent material.

- Compared with gravure printing, it is very fast printing technology.

- Compared with other printing technologies, flexographic printing technology supports a wide range of colours.

- You can use the water-based ink and oil-based ink of flexographic printing technology to print your spout pouch.

Limitations of Flexographic Printing Spout Pouches

- The technology is not advanced and therefore cannot produce complex and extensive works of art in your spray pocket.

- Compared with other printing technologies, the end colour of the printing spout pouch used in this technology is not bold.

- If you want high-end images, flexographic printing technology will not provide you with this.

- Flexographic printing technology is an ancient technology, and its design process lacks dynamics.

2. The benefits of printing spout pouches

There are several advantages to printing spout pouches. They include the following;

1) Sustainable Development

This is because they take up less space and many printed spout pouches are transported by cars. When the transportation space is reduced, it is equivalent to a reduction in fuel consumption. Therefore, the lower the fuel consumption, the lower the carbon emissions.

2) Durability

Compared with other packaging styles, printed spout pouches are durable. Therefore, you can guarantee that the packaging and its contents will not be damaged. This simply means that you will greatly reduce the number of customer complaints.

3) Brand

Printed spout pouches make your brand powerful, but simpler, more efficient, and productive. This is because they provide complete control in graphics compared to other packages. In addition, the printed spout pouch has an attractive shape that allows customers to distinguish them and can stand on the shelf. This makes them easy to take root in the minds of consumers.

4) Economy

Compared with alternative packaging, the cost of printing spout pouches is lower. This makes them the most economical and the best choice for packaging.

5) Eco-friendly

The printed spout pouch significantly reduces plastic. This means that they are made from natural resources rather than hard plastics.

3. Conclusion

Therefore, printed spout pouches are the best choice for flexible packaging. This is because they are cost-effective and do not allow compromised content and packaging.

Leave A Comment